Fire field logistics are nearly as critical as equipment on hand and personnel availability when responding to industrial hazard situations. Large fires require large volumes of water, which sometimes require multiple large diameter water supply hoses. The most convenient, reliable, and safest means of distributing large volumes of water over an entire facility is by constructing underground water delivery systems with above ground hydrant manifolds. These hydrant manifolds are then used in conjunction with large diameter water supply hose to supply the necessary water to pumps, nozzles, and foam proportioning equipment.

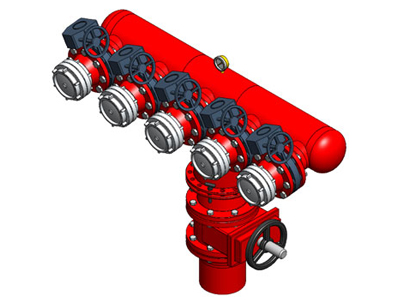

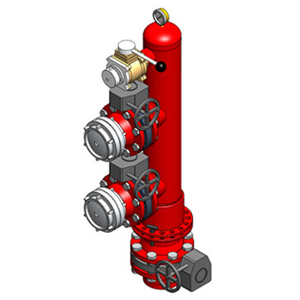

WILLIAMS FIRE & HAZARD CONTROL now brings conventional hydrant manifolds to a new functional level with an incorporated 360° rotating swivel built into the main riser of the unit. This swivel will allow the first responders to reposition the hydrant in the most advantageous direction depending on the location of the hazard and lock it into place using onboard swivel lock. This feature enhances the logistical efficiency of large volume water supply and reduces clutter around the hydrant manifolds. Choose from the vertical or Tee style and many available options to match your application requirements.

Features & Benefits

- Built with the industrial fire fighter in mind

- Reduction in total hose required due to eliminating initial bend radius

- Reduction in road blockage due to initial hose bends running across roadways

- Conservation of pressure due to shorter hoses needed

- Vertical style is ideal for highly congested areas

- Various sizes for a wide range of flows up to 10,000 gpm (37,854 Lpm)

- Potentially reduces the number of required hydrant locations by as much as 50%

- Robust design using swivels capable of supporting several tons of side load

- Fully serviceable with integrated swivel grease zerks

Available Options

- Various header designs (vertical stack, traditional Tee, or single 90° outlet)

- Various construction materials (carbon steel, 304L stainless steel, and 316L stainless steel)

- Various inlet and riser sizes (4”, 6”, 8”, 10” and 12”)

- Various discharge options (NST, BSP, Storz, etc.)

- Various discharge sizes (1½” – 12”)

- Standard integrated swivel lock to prevent movement after positioning

- Available with discharge valves, check valves, caps, or pressure gauges

- Available with integrated monitor mount

- Available with integrated automatic hydrant drain valve (below swivel)

- Available with hydrant inlet valve (between hydrant swivel and header connection)

Sizing Reference Guide

The below figures are based on a 24” underground header with 8’ of vertical piping extending to base of the hydrant. Loss numbers are from underground header inlet point to hydrant discharge (hose connection). Numbers will vary based on outlet valve and connection type/size selected.

Hydrant size recommendations made application specific.

These recommendations are based on hazards present and water flow required for suitable protection.

6” riser/hydrant (approximate Cv = 950)

1,000 gpm (3,785 Lpm) – 1 psi (0.07 bars) loss

2,000 gpm (7,571 Lpm)– 4.5 psi (0.31 bars) loss

3,000 gpm (11,356 Lpm) – 10 psi (0.69 bars) loss

8” riser/hydrant (approximate Cv = 1730)

3,000 gpm (11,356 Lpm) – 3 psi (0.21 bars) loss

4,000 gpm (15,142 Lpm) – 5.3 psi (0.37 bars) loss

6,000 gpm (22,712 Lpm) – 12 psi (0.83 bars) loss

10” riser/hydrant (approximate Cv = 2670)

6,000 gpm (22,712 Lpm) – 5 psi (0.34 bars) loss

8,000 gpm (30,283 Lpm) – 9 psi (0.62 bars) loss

10,000 gpm (37,854 Lpm) – 14 psi (0.97 bars) loss

Ordering Information

Please send inquiries with your specific application requirements to WILLIAMS FIRE & HAZARD CONTROL for custom configurations.