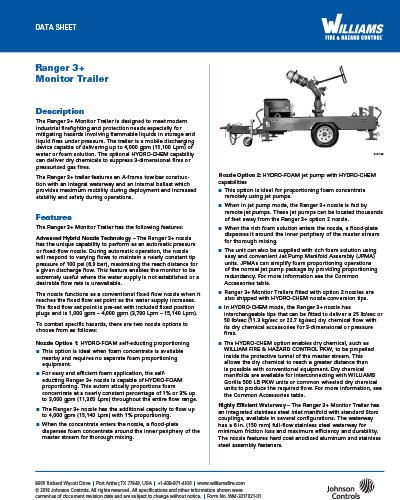

The Ranger 3+ Monitor Trailer is designed to address today’s industrial firefighting and protection needs, especially for mitigating hazards involving flammable liquids in storage and liquid fires under pressure. It is a mobile discharging platform capable of delivering up to 4,000 GPM (15,100 LPM) water or foam solution. With its optional Hydro-Chem capability, it can deliver dry chemicals to extinguish 3-dimentional fires or pressurized gas fires.

The Ranger 3+ trailer features an A-frame tow bar construction with integral waterway and an internal ballast, providing maximum mobility during deployment and increased stability and safety during operations.

Features & Benefits

Advanced “Hybrid” Nozzle Technology – The Ranger 3 nozzle has the unique capability to function as either an automatic pressure or fixed flow nozzle. In automatic operation, the nozzle will respond automatically to varying flow rates to maintain a nearly constant tip pressure at 100 psi (6.9 bars), thus maximizing effective reach range for a given discharge flow. This feature is useful in situations where stable water supply has not been established or desirable flow rate is not available. Once the nozzle reaches the fixed flow set point (between 1,000 – 3,000 gpm or 3,790 -11,360 Lpm, pre-set with included fixed position plugs) and as the water supply increases, the nozzle functions as a conventional fixed flow nozzle. To combat specific hazards, there are two nozzle options to choose from:

Ranger Trailer Nozzle Option 1 - Hydro-Foam Self Educting Proportioning – For easy and efficient foam application, the self-educting Ranger 3 nozzle is capable of Hydro-Foam proportioning which automatically proportions foam concentrate at a nearly constant percentage (1% or 3% up to 3,000 GPM or 11,360 Lpm) throughout the entire flow range. The Ranger 3+ nozzle has additional capacity to flow up to 4,000 gpm (15,140 Lpm) but only with 1% proportioning at the higher flow rate. After the concentrate enters the nozzle, a “flood-plate” disperses the rich water/foam solution around the inner periphery of the master stream for thorough mixing. This option is ideal when foam concentrate is available close by, and requires no separate foam proportioning equipment..

Ranger Trailer Nozzle Option 2 - Hydro-Foam Jet Pump plus Hydro-Chem Capabilities – This version of the Ranger 3 nozzle is capable of proportioning foam remotely using jet pumps. In Hydro-Foam jet pump mode, the nozzle is fed by remote jet pumps that can be located thousands of feet away from the incident at the foam source. After the concentrate enters the nozzle, a “flood-plate” disperses the rich water/foam solution around the inner periphery of the master stream for thorough mixing. The unit can also be supplied with foam using easy and convenient Jet Pump Manifold Assembly (JPMA) () units, that can simplify foam proportioning operations of the normal jet pump package by providing proportioning redundancy (see accessories list).

Monitor trailers fitted with this option also ship with Hydro-Chem nozzle conversion tips. In Hydro-Chem mode, the Ranger 3 nozzle is capable of delivering 25 lbs (11.3 Kg) or 50 lbs (22.7 Kg) of dry chemicals per second with its dry chemical accessories, for 3-dimensional or pressure fires. The Hydro-Chem option allows the dry chemical, such as WILLIAMS FIRE & HAZARD CONTROL PKW to be propelled inside the protective “tunnel” of the master stream. This enables the dry chemical to reach a greater distance than is possible with conventional equipment. Dry chemical manifolds are available for interconnecting with the WF&HC Gorilla 500 LB PKW units or common wheeled dry chemical units, to produce the required flow (see accessories list). The nozzle has interchangeable tips that can be fitted to provide a 25 or 50 lbs/sec (11.3 Kg or 22.7 Kg/sec) dry chemical flow rate.

Highly Efficient Waterway - The trailer has an integrated stainless steel inlet manifold with standard Storz couplings, available in several configurations. The monitor waterway has a 6” (150 mm) full-flow stainless steel waterway for minimum friction loss and maximum efficiency and durability. The nozzle features hard coat anodized aluminium and stainless steel assembly fasteners.

Easy and Safe Operations – The nozzle provides easy pattern control, ranging from full fog for personnel protection to straight stream for maximum reach and delivery (via a full wrap-around handle attached to the outer sleeve). The monitor allows a full monitor articulation of 360˚ rotation, and down to -15˚ and up to +75˚ vertical travel for the tiller bar models. The trailer is designed with built-in ballast for stability using the weight of water during operations. The ballast is below an anti-skid grip deck for firm footing even when the surface is completely wet. Flowing up to 4,000 GPM, a firefighter operating the device using the standard tiller-bar or gears will experience the freedom of smooth, rapid horizontal and vertical movement. For enhanced safety and ease of use, an electric/hydraulic version is also available, which can be remotely controlled from up to 300 ft (91 m) away and with gear operation as backup. The remote-controlled unit is fully self-contained and requires no additional power supply, as it features dual on-board deep cycle batteries and an on-board charger. Simply leave it plugged in at the firehouse to maintain battery charge and take advantage of hours of wireless remote operation when deployed.

For the European market, a version built and certified to European Road Legal standards is available as a dual axle trailer.

Ranger3+ Range and Elevation Performance

Operating Pressure 100 psi

| Nozzle Angle 30° | Nozzle Angle 45° | Nozzle Angle 80° | |||||||

|

Flow Rate (gpm) |

Max Range (ft) |

Max Height (ft) |

Height Location (ft) |

Max Range (ft) | Max Height (ft) | Height Location (ft) |

Max Range (ft) |

Max Height (ft) | Height Location (ft) |

| 1000 | 211 | 34 | 143 | 190 | 76 | 127 | 87 | 94 | 59 |

| 2000 | 286 | 45 | 191 | 211 | 95 | 141 | 112 | 130 | 75 |

| 3000 | 309 | 49 | 207 | 232 | 105 | 155 | 117 | 150 | 78 |

| 4000 | 333 | 53 | 223 | 276 | 124 | 185 | 121 | 162 | 81 |

Notes:

Above data for straight stream in still air to 5mph tail wind condition using water only.

Foam decreases range 5 - 20% in still air. Winds increase stream aspiration and reduce range further.

Ranger3+ Range and Elevation Performance

Operating Pressure 7 BAR

| Nozzle Angle 30° | Nozzle Angle 45° | Nozzle Angle 80° | |||||||

|

Flow Rate (lpm) |

Max Range (M) |

Max Height (M) |

Height Location (M) |

Max Range (M) | Max Height (M) | Height Location (M) |

Max Range (M) |

Max Height (M) | Height Location (M) |

| 3785 | 64 | 10 | 44 | 58 | 23 | 39 | 27 | 29 | 18 |

| 7571 | 87 | 14 | 58 | 64 | 29 | 43 | 34 | 40 | 23 |

| 11356 | 94 | 15 | 63 | 71 | 32 | 47 | 36 | 46 | 24 |

| 15142 | 102 | 16 | 68 | 84 | 38 | 56 | 37 | 49 | 25 |

Notes:

Above data for straight stream in still air to 5mph tail wind condition using water only.

Foam decreases range 5 - 20% in still air. Winds increase stream aspiration and reduce range further.

Ordering Information

Standard Ranger 3+ Trailers

| Part Number | Nozzle Type | Control Type | 5" Inlets | 6" Inlets | Trailer Type |

| 10260 | Self-educting (selectable 1%/3%) | Tiller Bar | 4 | Single axle | |

| 10261 | Self-educting (selectable 1%/3%) | Tiller Bar | 3 | Single axle | |

| 20468 | Self-educting (selectable 1%/3%) | Tiller Bar | 4 | Single axle | |

| 10266 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Tiller Bar | 4 | Single axle | |

| 10267 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Tiller Bar | 3 | Single axle | |

| 19825 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Tiller Bar | 4 | Single axle | |

| 19859 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Tiller Bar | 4 | European, dual axle | |

| 10262 | Self-educting (selectable 1%/3%) | Gear Operated | 4 | Single axle | |

| 10263 | Self-educting (selectable 1%/3%) | Gear Operated | 3 | Single axle | |

| 20469 | Self-educting (selectable 1%/3%) | Gear Operated | 4 | Single axle | |

| 10268 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Gear Operated | 4 | Single axle | |

| 10269 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Gear Operated | 3 | Single axle | |

| 20471 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Gear Operated | 4 | Single axle | |

| 10264 | Self-educting (selectable 1%/3%) | Wireless Remote Control | 4 | Single axle | |

| 10265 | Self-educting (selectable 1%/3%) | Wireless Remote Control | 3 | Single axle | |

| 20470 | Self-educting (selectable 1%/3%) | Wireless Remote Control | 4 | Single axle | |

| 10270 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Wireless Remote Control | 4 | Single axle | |

| 10271 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Wireless Remote Control | 3 | Single axle | |

| 20472 | Hydro-Chem/Hydro-Foam (jet pump feeding foam) | Wireless Remote Control | 4 | Single axle |

Notes:

Self-educting is feasible up to 4000 GPM (15,100 LPM) at 1% and 3000 GPM (11,300 LPM) at 3%.

Hydro-Chem/Hydro-Foam models include foam proportioning system and can apply dry chemical.

19859 is European Road Legal.

May also use jet pump manifold JPMA 2-180 proportioner for simplified foam proportioning operations.

Custom trailers are available with additional lead time and cost.

Ranger 3+ Trailer Common Accessories (Sold Separately)

| Part Number | Description |

| 10227 | Kit, HYDRO-CHEM accessories, monitor trailer applications, up to qty (14) 350 lbs common wheeled dry chemical units |

| 15461 | Kit, HYDRO-CHEM accessories, monitor trailer applications, up to qty (7) 350 lbs common wheeled dry chemical units |

| 10228 | Kit, HYDRO-CHEM accessories, monitor trailer applications, up to qty (2) 500 lbs Gorilla dry chemical units |

| 20121 | Kit, adapter, Ranger 3+, BI JRC, converts Ranger 3+ jet pump accessories to British Instantaneous connection |

| 20122 | Kit, adapter, Ranger 3+, BSP JRC, Ranger 3+ jet pump accessories to BSP connection |

Alternative to jet pumps for foam proportioning, Jet Pump Manifold Assemblies may be used.

JPMA 2-180 Standard Units (Jet Pump Manifold Assembly)

| Part Number | Water Inlet Connections | Rich Solution Discharge Connections |

| 10229 | 2.5" (F)NST | 4" Storz |

| 16214 | 2.5" (M)BI | 4" Storz |

| 10230 | 2.5" (F)NST | 5" Storz |

| 16215 | 2.5" (M)BI | 5" Storz |

| 10231 | 2.5" (F)NST | 6" Storz |

| 16216 | 2.5" (M)BI | 6" Storz |

Adapters/Etc.

| Part Number | Inlet (from JPMA 2-180) | Outlet (to 3" Ranger 3+ Foam Hose) |

| 15848 | 4" Storz | 3" (M)NPSH |

| 15849 | 5" Storz | 3" (M)NPSH |

| 20131 | 6" Storz | 3" (M)NPSH |

Notes:

The JPMA 2-180 will proportion up to 180 GPM (680 LPM) of foam concentrate.

The JPMA 2-180 will facilitate 1% proportioning with up to 8,000 GPM (30,000 LPM) and 3% with up to 6,000 gpm (22,700 LPM) of water.

NST and NH are compatible, BI stands for British Instantaneous.

For 3% proportioning at 8,000 GPM (30,000 LPM) with JPMA, consult factory.

Customized models are available but lead time and cost may be affected.